[ad_1]

Our RC interest has been round for a lot of many years, and it has been, for probably the most half, a hands-on DIY pursuit. At first, all there was to select from have been builder’s kits. In latest occasions, the interest has developed to incorporate easier-to-assemble “virtually able to fly” (ARF) planes, which significantly sped the event of skilled RC pilots. This, nonetheless, got here at the price of modelers having much less workshop expertise. This text highlights a number of the fundamentals of constructing a mannequin airplane from a equipment. Let’s get began.

Tech Tip

Rule primary for equipment constructing: Learn the directions. Learn them a number of occasions earlier than you start to connect issues collectively. In case you have problem understanding them, attain out to an skilled pal for assist. You might want to know what you’re doing and easy methods to do it earlier than you start.

STEP 1 CREATE A HEALTHY WORK ENVIRONMENT

The most effective elements of being a model-airplane builder is placing collectively a specialised workshop. More often than not, this occurs in a nook of the storage or within the basement, so you possibly can comprise all of the wooden shavings and never get the remainder of your property soiled. All you actually need is a bench or two, and these may be made out of cheap interior-grade hollow-core doorways and 2X4 lumber from a home-improvement middle. Your bench must be straight and true, and fact be instructed, your workbench ought to be your first constructing challenge if you wish to grow to be a equipment builder.

A neat workbench is a superb begin for any constructing challenge, whether or not it’s a equipment or an almost-ready-to-fly.

Holding your bench clear, organized, and properly lit will go a great distance in rushing the model-building course of. A useful shelf above your bench is sweet for storing often-used provides and a roll-around toolbox/cupboard retains instruments useful and inside simple attain. I’ve additionally discovered it useful to make a smaller work board topped with stick-on cork materials to be used as a secondary work floor. You’ll be able to assemble and construct lengthy elements on the principle workbench whereas assembling smaller objects, like tail surfaces and wing halves, on the constructing board. That is extra handy in case you don’t have the room for 2 full-size benches in your work space.

Holding your instruments useful and inside simple attain with a roll-around software cupboard speeds building.

Good overhead lighting is a should. You’ll take pleasure in constructing extra in case you can simply see what you might be doing. Ceiling store lights—particularly, single and twin fluorescent lighting—is surprisingly cheap and available at {hardware} shops and home-improvement facilities. Dangle them over your workbench above head-banging peak. If you are at it, set up a few store energy strips in an effort to simply provide energy to the sunshine fixtures and your energy instruments.

Fluorescent or LED lights are a should. You’ll take pleasure in constructing extra in case you can simply see what you might be doing.

STEP 2 GENERATE A PLAN OF ATTACK

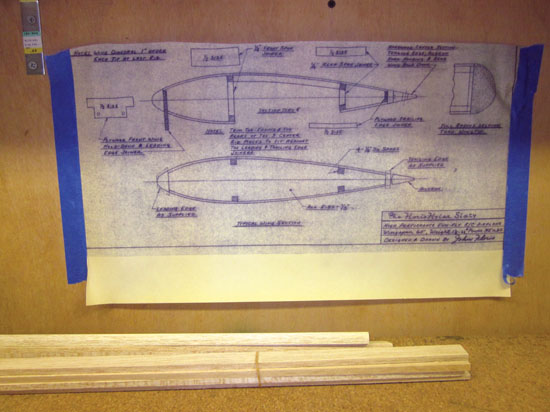

That is the principle distinction between kits and ARFs: You must construct the equipment aircraft, and that requires plans, that are normally included with the equipment elements. A great way to cope with the plans is to chop them aside and separate the assorted elements into smaller sections. A few of the drawings (cross-sections and particulars) present how issues go collectively. I wish to tape these to the wall in order that they don’t take up room on the workbench and I can discuss with them all through the construct with out interruption. Place the drawings for the tail surfaces, fuselage, and wing panels in your work floor in an effort to construct the elements on high of them. I like to begin constructing kits with the fuselage first since all the opposite elements are hooked up to it. If that is your first equipment aircraft, begin with the smaller tail surfaces and construct them on the separate constructing board.

Right here, the 2 fuselage sides are being assembled. The positions of the elements are decided by

measuring them from the plans.

Use the side-view drawing to work out the location of the formers and doubles that the edges are made up of. Relating to gluing the 2 sides of the fuselage along with the formers, use a straight reference line as a information. Draw centerlines on all of the formers after which, as you add the formers and draw the edges collectively on the tail, align the centerlines with the reference line. You’ll be able to draw a line on the workbench or use one of many border strains which are drawn on most plans.

It’s also vital to guard your plans to forestall your elements from being caught to the paper. I exploit clear plastic Plan Protector from Nice Planes, however you can even use clear movie overlaying. You may as well use small sheets of wax paper or plastic meals wrap positioned beneath particular gluing factors to guard your planes.

Whether or not you utilize business plan protectors or some plastic meals wrap, stopping your elements from sticking to the paper is vital.

With plan particulars taped to the wall, you possibly can discuss with them throughout building and so they gained’t take up room in your constructing floor.

STEP 3 ENSURE PROPER ALIGNMENT

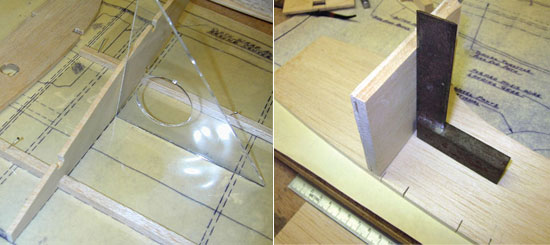

As you get into the construct, you will need to use squares and 90-degree triangles to assist preserve elements sq. and correctly aligned as your glue joints dry. Measure your facilities and draw centerlines on elements in an effort to, at a look, see if they’ve been put in accurately. Whenever you construct a wing panel, you first begin by pinning the underside spar securely in place over the plans. You then add the assorted ribs to the spar, ensuring they’re positioned vertically utilizing a builder’s triangle as a information. Tack-glue every rib into place after which, after putting in the highest spar, end gluing the ribs into place. At all times take your time and ensure every little thing strains up correctly earlier than ending the gluing.

Use squares and 90-degree triangles to assist preserve elements sq. and correctly aligned as your glue joints dry. Measure your facilities and draw centerlines on elements in an effort to, at a look, see if they’ve been put in accurately.

Tech Tip

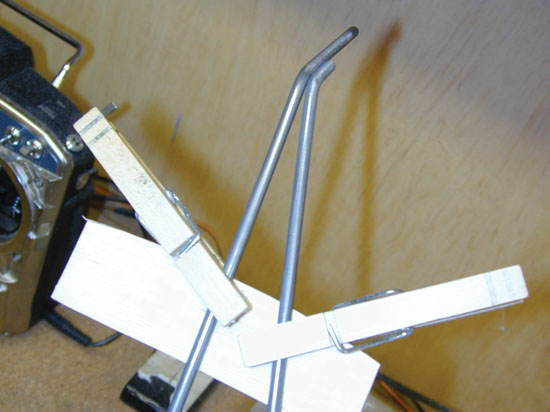

There are many glues to select from on the interest retailers. As a normal rule, CA glue is available in skinny, medium, and thick viscosities. Use skinny CA for tight-fitting joints and medium CA for the place there is perhaps a slight hole between elements. Thick CA glue normally takes a bit of longer to dry, so it’s a sensible choice when gluing elements collectively the place you’ll want a bit of extra time to get the alignment right, akin to for lengthy items of wing sheeting. Straight pins, tape, and clothespins are all nice for holding items collectively because the glue dries.

STEP 4 MAKE CLEAN CUTS

Relating to reducing elements to form or to suit, at all times use a pointy hobby-knife blade. As you utilize them, the blades will grow to be boring, and this may have an effect on the standard of the minimize. Utilizing boring blades additionally requires extra reducing strain, and this may be harmful since you may slip when making the minimize. Make your cuts, utilizing a straightedge as information, then make a number of gentle passes to finish the cuts in balsa sheeting. For objects like main edges, spars, and different “stick” inventory, I discover it useful to chop them longer than wanted. I glue them into place, then use a razor noticed to chop off many of the extra size; I end it off utilizing a sanding block. This produces a clear and correct completed meeting. That is particularly vital for the wing middle ribs, the place the wing panels are glued collectively, and for the wingtip ribs, the place you’ll later connect the wingtips.

STEP 5 BUILD TO SUIT

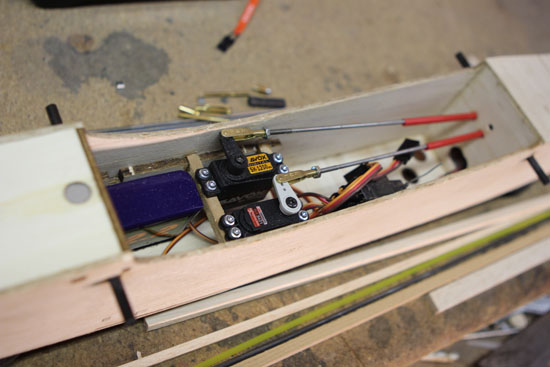

An vital a part of constructing a equipment is the strategy planning stage. You’ll have to determine early on what radio gear and servos you will use, and what sort of energy system you propose to put in. Having your {hardware} useful makes your construct go smoother as you possibly can prep varied elements earlier than they’re glued into place. Take the firewall, as an illustration. With my newest construct, I went with a Himax brushless motor from Maxx Merchandise for energy. Earlier than gluing the firewall into place, I used the motor-mount {hardware} to find out the place the attachment holes wanted to be drilled. The identical goes for the servo rails. By having the servos readily available, you possibly can decide the servo-rail spacing. Having the battery pack and pace controller, you can even work out the place every little thing might want to match earlier than gluing formers and doublers into place.

A part of this planning additionally contains the structure and set up of your pushrods for the elevator and rudder. You might want to work this out earlier than you end sheeting the highest and backside of the fuselage. This can be very tough to put in pushrods and their information tubes after all of the sheeting is in place. Additionally, bear in mind to put in the highest and backside sheeting in order that the grain runs throughout the width of the fuselage. This provides extra power than in case you ran the grain from nostril to tail.

Glue the highest and backside fuselage sheeting (cross-grain) in place after putting in the pushrods and information tubes.

Right here is the Himax motor powering my new challenge. I used the motor mount to find out the location of the attachment holes.

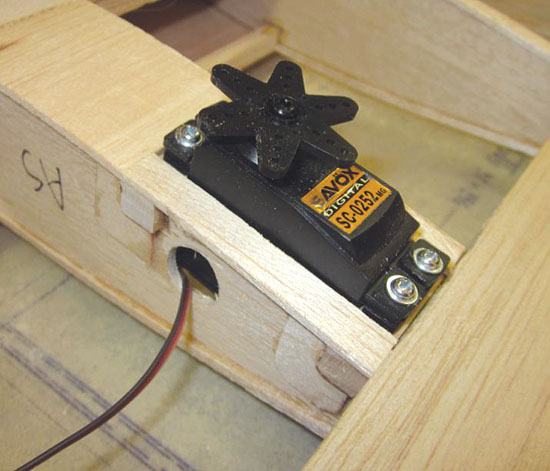

When putting in your servos, ensure that the servo arms don’t intrude with the edges of the fuselage or every other gear within the radio compartment.

STEP 6 SET UP YOUR LINKAGES

Because the pushrods switch the servo’s motion to the management surfaces, it’s best to set up the servos first after which the management surfaces earlier than you possibly can arrange the linkages. You should definitely use hardwood, akin to spruce, and even 1/2-inch-wide strips of 1/4-inch-thick plywood to make robust servo mounts and rails. Set up the rubber grommets and brass inserts into the servo’s attachment tabs after which drill pilot holes by them and into the servo rails. I exploit cap-head screws from RTL Fasteners for all my {hardware}, however most servos include servo mounting screws. You should definitely add a drop of skinny CA to the screw holes to assist “harden” the wooden in order that the screw threads gained’t strip out.

I like utilizing a mixture of Nice Planes and Du-Bro Merchandise to make up my management programs. Twelve-inch-long pushrods with threaded ends and mating clevises can be found from Nice Planes. It additionally has clevises which are soldered to the opposite finish of the wire pushrod. This setup works properly and permits for about half an inch of size adjustment. For my giant 60-size Florio Flyer, I used this setup, with servos mounted simply in entrance of the stabilizer. Ensure you set up the Du-Bro management horns in order that the attachment holes line up with the hinge strains of the management surfaces.

Whenever you set up your management linkage, middle your management floor and fix your management horn in order that the holes are lined up with the hinge line.

STEP 7 SOLDER THE HEAVY PARTS

Relating to soldering large-gauge wire, akin to for pushrods and clevises, at all times clear the elements with sandpaper and use high-silver-content solder and correct flux. Do the identical for soldering the wire touchdown collectively. I discover that Keep Brite silver solder and liquid flux work nice. You will need to use a number of warmth when soldering; I exploit an 80-watt soldering iron with wonderful outcomes.

To finish up with a straight and correctly aligned touchdown gear, you first have to wash all of the elements after which connect the bottom ends to the fuselage with the required straps. Subsequent, use a size of wooden and a few clothespins to clamp the struts into alignment in order that the axles ends may be soldered collectively. I exploit skinny copper wire to bind the entrance and rear wires collectively, wrapping the solder joint space tightly and neatly. Apply a number of drops of flux to the wire and the gear struts after which apply warmth. Place the soldering iron beneath the wraps, and apply the solder to the highest. When the wires and kit struts are scorching sufficient, the solder will movement easily into the joint space. Don’t transfer the gear till the solder has cooled. Verify the alignment of the second aspect, and repeat the method to finish the job. After the solder has cooled, take away the gear from the fuselage and clear the solder joints utilizing a wire brush and a few solvent, akin to rubbing alcohol, to take away the leftover flux. Set up the wheel and reattach the touchdown gear after you’ve coated the fuselage.

To finish up with a straight and correctly aligned touchdown gear, you first have to wash all of the elements after which connect the bottom ends to the fuselage with the required straps. Subsequent, use a size of wooden and a few clothespins to clamp the struts into alignment in order that the axles ends may be soldered collectively. I exploit skinny copper wire to bind the entrance and rear wires collectively, wrapping the solder joint space tightly and neatly. Apply a number of drops of flux to the wire and the gear struts after which apply warmth. Place the soldering iron beneath the wraps, and apply the solder to the highest. When the wires and kit struts are scorching sufficient, the solder will movement easily into the joint space. Don’t transfer the gear till the solder has cooled. Verify the alignment of the second aspect, and repeat the method to finish the job. After the solder has cooled, take away the gear from the fuselage and clear the solder joints utilizing a wire brush and a few solvent, akin to rubbing alcohol, to take away the leftover flux. Set up the wheel and reattach the touchdown gear after you’ve coated the fuselage.

STEP 8 JOIN THE PANELS

To strengthen the middle part the place the 2 wing panels are glued collectively, you must wrap the middle seam with some fiberglass tape and glue it into place with slow-setting epoxy resin. To make the job a bit simpler, set up the fiberglass tape to the highest and backside surfaces individually and overlap the items on the main and trailing edges. To make the epoxy resin simpler to use, I exploit equal elements of half A and B after which some denatured alcohol in order that it’s all combined collectively in thirds. Lay the tape into place, dribble the resin on high of the fiberglass, then place a number of the clear plastic plan protector over the joint. Utilizing some scraps of balsa sheets, squeegee the resin beneath the clear plastic in order that it utterly fills the weave of the reinforcement tape. Tape the clear plastic in place till the resin units up utterly. Then take away the plastic sheet, and repeat on the opposite aspect of the wing. When the job is completed, you’ll have a really easy floor produced from the plastic sheet and the overlapped sections of tape shall be correctly bonded collectively and flattened out. No sanding is required, and the overlaying materials will stick properly to the graceful epoxy floor.

Right here, the fiberglass tape and epoxy have been coated with the clear plastic. Left: After eradicating the plas

STEP 9 FIT THE HINGES

As soon as all of your elements are constructed and assembled, you must match all of the hinges (however don’t glue them into place till after the mannequin has been coated). Du-Bro Merchandise makes nice plastic pinned hinges, and you will get CA glue–fashion hinges from Radio South. It’s as much as you which of them one to make use of.

Correctly put in plastic pinned hinges will present easy, bind-free management response. Du-Bro has a hinge-slotting software set that makes the set up simple.

For lengthy management surfaces, just like the ailerons, you will need to set up all of the hinges in order that they’re in alignment with one another.

STEP 10 COVER AND FINISH IT

Prepared for takeoff? Nearly! Earlier than you possibly can fly your new kit-built mannequin airplane, you’ll have to cowl it. There are a number of manufacturers of coverings out there together with plastic movies, akin to Hangar 9’s UltraCote and Prime Flite’s MonoKote, in addition to painted material material, akin to Solartex from Balsa USA and SIG Mfg.’s Koverall. Every model comes with detailed directions, however in case you need assistance, ask an skilled pal for help. It’s the overlaying and ending that actually units your kit-built mannequin other than the remainder.

For a easy overlaying job, you must sand all of your airplane’s elements easy. There ought to be no gaps or uneven glue joints. Utilizing a sanding block is the most effective technique to provide a fair floor.

[ad_2]